Henwi HWFCL- 1 Nozzle Automatic Powder Filling Bottling Packing Machine Powder Auger Bottling Filler Sealer Machine with Plastic Bottle Cap Capping Sealing Machine Double Sides Square Bottle & Round Bottle Labeling Machine Production Line

Henwi HWFCL- 1 Nozzle Automatic Powder Filling Bottling Packing Machine Powder Auger Bottling Filler Sealer Machine with Plastic Bottle Cap Capping Sealing Machine Double Sides Square Bottle & Round Bottle Labeling Machine Production Line

Couldn't load pickup availability

1. Introduction

This equipment is widely used in powder material filling and bottling, especially in food, medicine, cosmetics, daily chemical industry, etc. It can work with capping machine and labeling machine and other machines as a production line.

By setting the filling volume and parameters on the control panel, the system will automatically complete the filling process according to the settings. During the filling process, the screw rotates to transport the powder to the filling port to ensure that the weight or volume of each bottle of material meets the preset requirements.

Suitable for many different shape container, like bottle, jar, can, tin, sachet, barrel, tank, etc. Or different material container, like plastic, glass, aluminum, wood, paper, PET, iron steel, etc.

2. Specification

1 Nozzle Automatic Powder Filling Bottling Packing Machine

|

1

|

Filling method

|

Screw metering / Cup metering

|

|

2

|

Auger volume

|

30/50L(can be customized)

|

|

3

|

Feeder volume

|

100L(can be customized)

|

|

4

|

Machine material

|

SUS 304 (can be customized SUS316L)

|

|

5

|

Filling volume

|

2-10g, (can be customized / replaced)

10-100g,

50-500g,

100-1000g,

200-2000g,

500-5000g,

|

|

6

|

Filling accuracy

|

±1%(different volume and material,accuracy will be little different)

|

|

7

|

Filling speed

|

30-60 BPM

|

|

8

|

Weight

|

400KG

|

|

9

|

Dimension

|

2100*1200*2050mm

|

|

10

|

Protective device

|

Outage alarm on shortage of powder in the hopper.

|

1 Station 4 Wheels Bottle Capping Sealing Machine

|

1

|

Qty of capping wheels

|

4 wheels

|

|

2

|

Applicable cap diameter

|

25-80mm

|

|

3

|

Capping speed

|

1800-3600 bottles/hour

|

|

4

|

Material

|

304 stainless steel

|

|

5

|

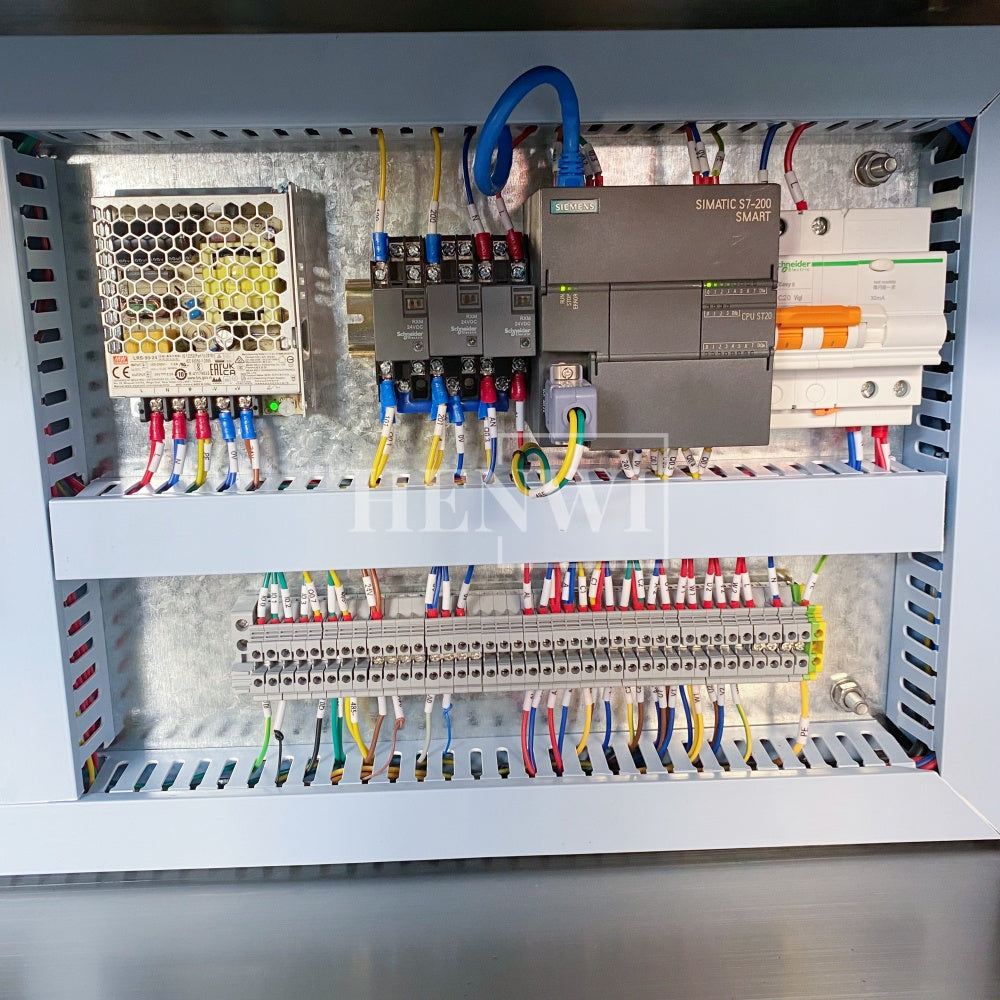

Program controller

|

Touch panel screen & PLC control

|

|

6

|

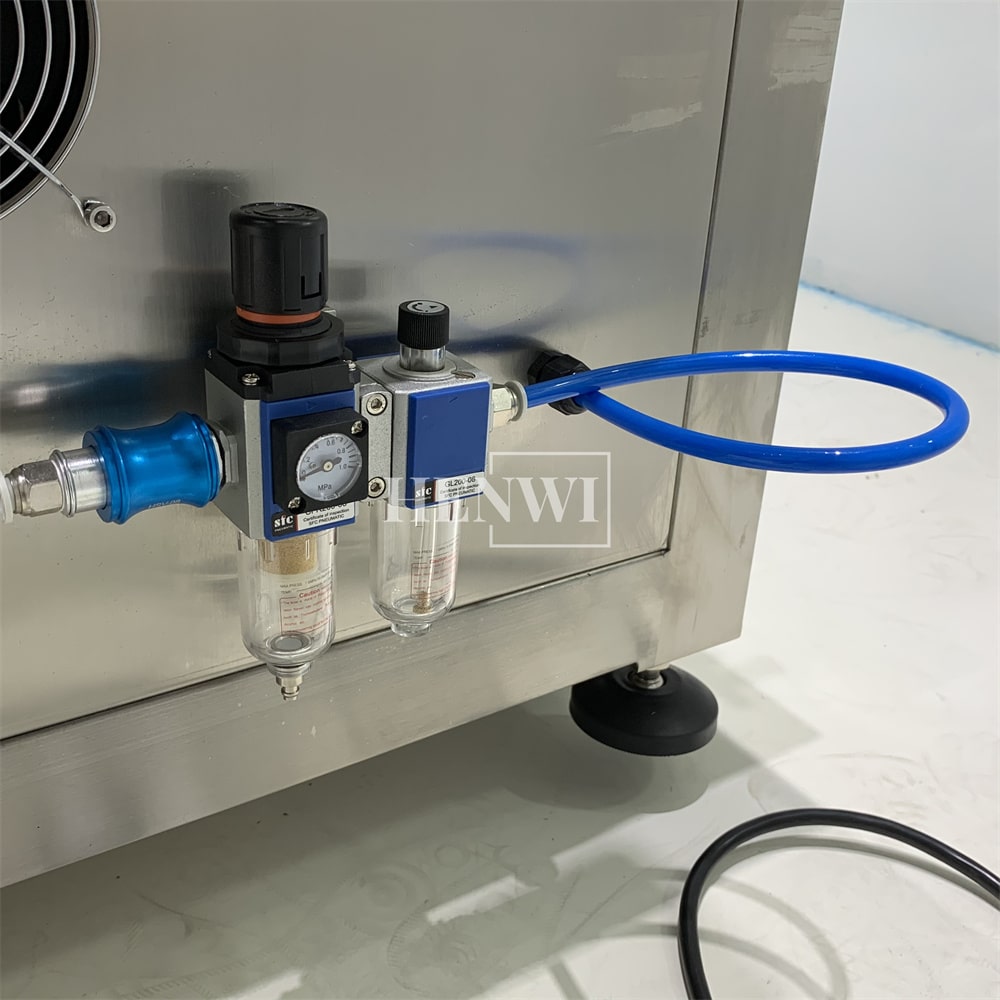

Air pressure

|

0.5 -0.7mpa

|

|

7

|

Power

|

2kw

|

|

8

|

Frequency inverter

|

Delta/Coreken

|

|

9

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

10

|

PLC

|

Siemens

|

|

11

|

Touch screen

|

Siemens

|

|

12

|

Servo parts

|

Inovance

|

|

13

|

Sensor

|

SICK/KEYENCE

|

|

14

|

Motors

|

ZD

|

|

15

|

Pneumatic components

|

AirTAC

|

|

16

|

Machine size

|

2000x800x1600 (mm)

|

|

17

|

Weight

|

350 (KG)

|

|

18

|

Power supply

|

220V/50Hz

|

Automatic 2 Sides Square Flat Bottle & Round Bottle Labeling Machine

|

1

|

Machine name

|

Automatic double sides square &

round bottle labeling machine

|

|

2

|

Applicable round bottle size

|

Diameter: 30-100mm

|

|

3

|

Applicable square bottle size

|

Width: 30-80mm

|

|

4

|

Applicable labels size

|

Hight: 15-130mm

|

|

5

|

Labeling speed

|

1500-6000 bottles/hour

|

|

6

|

Material

|

304 stainless steel

|

|

7

|

Program controller

|

Touch panel screen & PLC control

|

|

8

|

Air pressure

|

0.5 -0.7mpa

|

|

9

|

Power

|

3kw

|

|

10

|

Frequency inverter

|

Delta/Coreken

|

|

11

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

12

|

PLC

|

Siemens

|

|

13

|

Touch screen

|

Siemens

|

|

14

|

Servo parts

|

Inovance

|

|

15

|

Sensor

|

SICK/KEYENCE

|

|

16

|

Servo motors

|

TECO

|

|

17

|

Stepper motors

|

ZD

|

|

18

|

Pneumatic components

|

AirTAC

|

|

19

|

Machine size

|

3000x1500x1800 (mm)

|

|

20

|

Net weight

|

480 (KG)

|

|

21

|

Power supply

|

220V/50Hz

|

|

22

|

Wooden box packing size

|

2400x1400x2000 (mm)

|

|

23

|

Wooden box packing weight

|

530 (KG)

|

3. Production Line

(1) Bottle Unscrambler

(2) SUS Storage Tank

(3) Automatic Bottling Filling Machine

(4) Automatic Bottle Capping Machine

(5) Automatic Cap Feeding Machine

(6) Automatic Bottle Clamping Conveyor

(7) Aluminum Foil Induction Sealing Machine

(8) Automatic Bottle Labeling Machine

(9) Finished Bottle Collecting Table

(10) Other Accessory Machine

Share