Henwi HWFCL- 1 Nozzle Full-Auto Liquid Mixing Heating Bottling Filling Machine One Head Bottle Filler With Mixer Heater with Semi Automatic Bottle Cover Cap Capping Labeling Machine Line with Handheld Induction Sealing Device with Cooling Tunnel

Henwi HWFCL- 1 Nozzle Full-Auto Liquid Mixing Heating Bottling Filling Machine One Head Bottle Filler With Mixer Heater with Semi Automatic Bottle Cover Cap Capping Labeling Machine Line with Handheld Induction Sealing Device with Cooling Tunnel

Couldn't load pickup availability

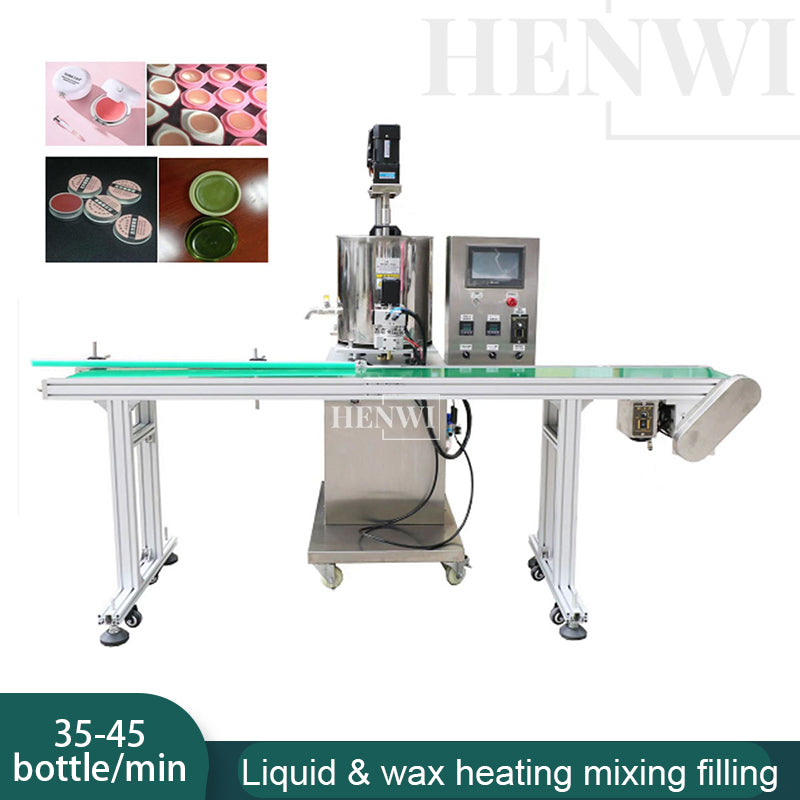

1. Introduction

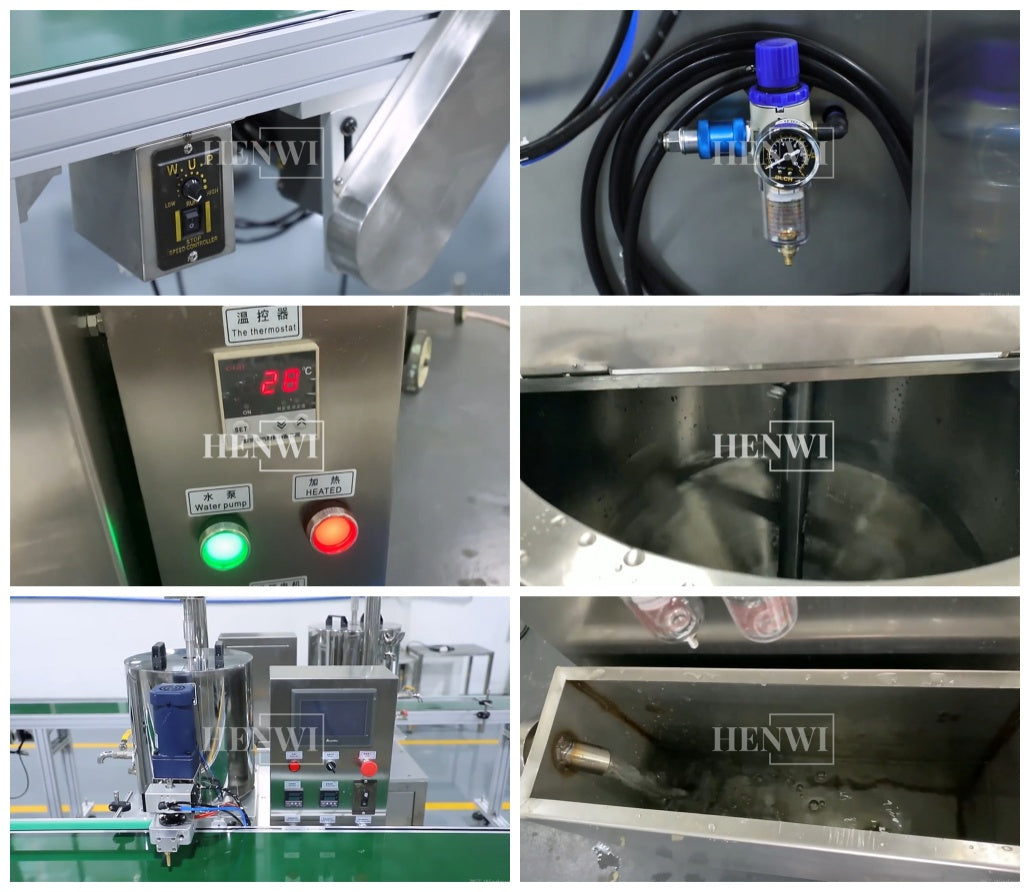

(1) Constant temperature stirring: equipped with heating and stirring system, it can keep the liquid at a suitable temperature during the filling process, while ensuring that the ingredients are evenly mixed.

(2) Flexibility: the stirring speed and temperature can be adjusted according to the characteristics of different products.

Please inquire us if you're not sure whether this machine can process your product or not.

This machine series is suitable for filling hot-melt liquid cosmetics & food & pharmaceutical & chemical products into bottle or jar or other containers, like vaseline, hair wax, candle, builder gel, balm oil, solid perfume, air fresher, petroleum jelly, etc.

2. Specification

1 Nozzle Full-Auto Liquid Mixing Heating Bottling Filling Machine

|

1

|

Qty of filling head

|

1 head

|

|

2

|

Filling range

|

10-100ML;

or customized

|

|

3

|

Filling speed

|

35-45 bottles/min

|

|

4

|

Main functions

|

Liquid mixing;

Liquid heating;

Liquid filling;

|

|

5

|

Mixing speed

|

0~90 RPM

|

|

6

|

Total power

|

2.2KW

|

|

7

|

Constant temperature method

|

Hot water or oil circulation

|

|

8

|

Filling accuracy

|

±1%.

|

|

9

|

Material

|

316L/304 stainless steel

|

|

10

|

Air pressure

|

0.4-0.6mpa

|

|

11

|

Capacity of material tank

|

20L, double layers as 1 jacket

|

|

12

|

Pump type

|

Gear pump with magnetic valve

|

|

13

|

Material supplement method

|

Direct suction/Manual

|

|

14

|

Pneumatic components

|

AirTAC

|

|

15

|

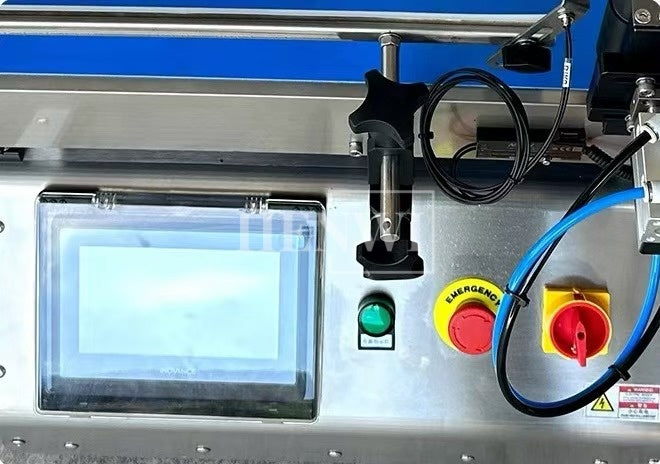

Touch screen

|

Delta / MAGS

|

|

16

|

PLC

|

Delta / MAGS

|

|

17

|

Machine size

|

800*820*1600 mm

|

|

18

|

Weight

|

80 (KG)

|

|

19

|

Conveyor

|

3 meters with guardrail

|

|

20

|

Power supply

|

220V/50Hz

110V/60Hz

|

Single Lane Chilling Tunnel Industrial Quick Freezer Tunnel

| 1 |

Voltage specification

|

380V/50Hz/ 3 phase

|

| 2 |

Freezing temperature

|

-18 ºC

|

| 3 |

Compressor power

|

5HP / 4.5KW

|

| 4 |

Optional conveyor

|

Single lane

|

| 5 |

Cooling way

|

Air Cooling by fans

|

| 6 |

Machine size

|

3000*800*1500mm

|

| 7 |

Conveyor belt size

|

4000*300mm

|

| 8 |

Machine weight

|

750KG

|

| 9 |

Freezing time

|

1-3 min

|

| 10 |

Special functions

|

Time setting and temperature setting

|

| 11 |

Material

|

SUS304

|

| 12 |

Compressor

|

Maneurop French

|

| 13 |

Customized length

|

4-8 meter

|

Semi-Auto 4 Wheels Bottle Screwing Capping Sealing Machine

|

1

|

Qty of capping wheels

|

4 wheels

|

|

2

|

Applicable cap diameter

|

20-80mm

|

|

3

|

Capping speed

|

1200-1800 bottles/hour

|

|

4

|

Material

|

304 stainless steel

|

|

5

|

Controller

|

Button control

|

|

6

|

Automation

|

Desktop, semi automatic

|

|

7

|

Air pressure

|

0.5 -0.7mpa

|

|

8

|

Power

|

0.3kw

|

|

9

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

10

|

Motors

|

DY

|

|

11

|

Pneumatic components

|

AirTAC

|

|

12

|

Machine size

|

500x380x700 (mm)

|

|

13

|

Weight

|

35 (KG)

|

|

14

|

Power supply

|

220V/50Hz

|

Handheld Aluminum Foil Induction Sealing Device

|

1

|

Rated voltage

|

220V/50HZ

|

|

2

|

Power adjustment

|

500-1200W

|

|

3

|

Sealing speed

|

0.5-4 seconds each time

|

|

4

|

Material

|

imported ABS

|

|

5

|

Net weight

|

0.9kg

|

|

6

|

Sealing diameter

|

20-120mm

Customized

|

|

7

|

Dimensions

|

135*135*235mm

|

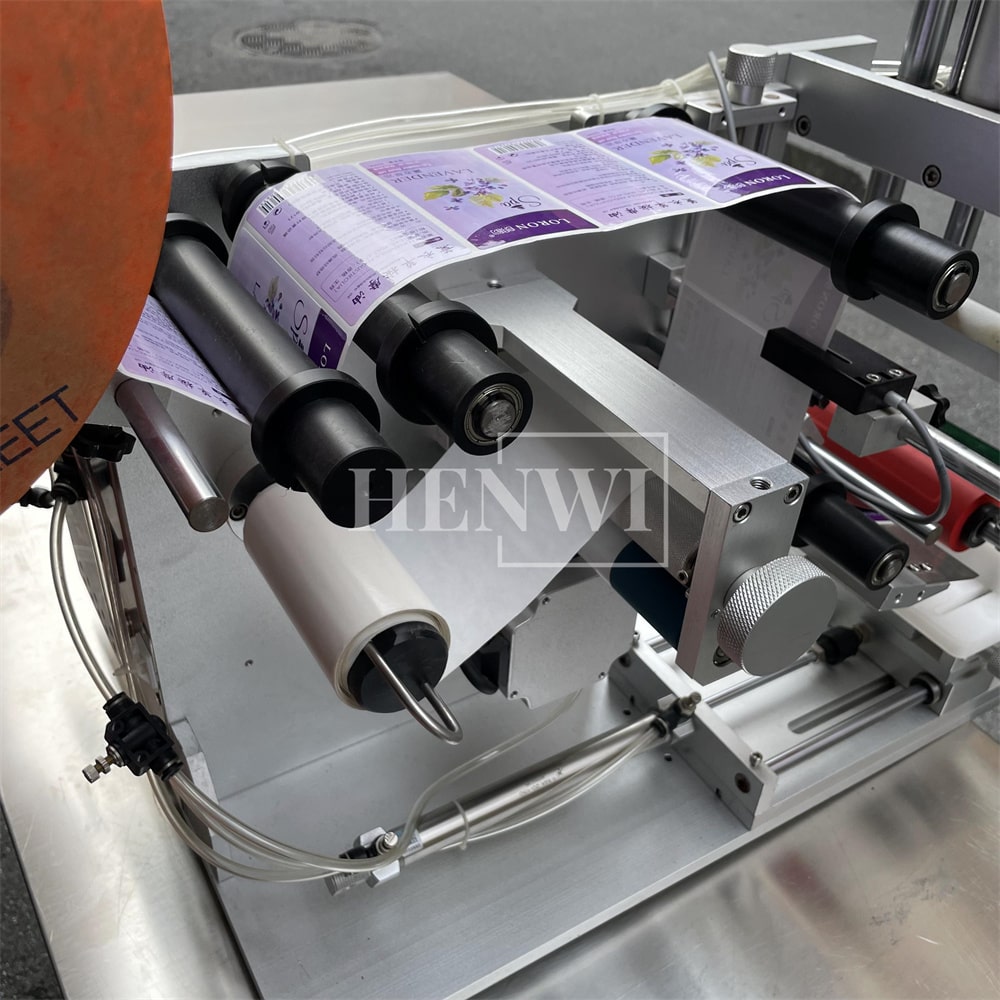

Vertical Semi Auto Model Round Bottle Labeling Machine

|

1

|

Machine name

|

Manual vertical model round bottle labeling machine

|

|

2

|

Applicable round bottle size

|

Diameter: 30-100mm

Height: 15-250mm

|

|

3

|

Applicable labels size

|

Hight: 15-130mm

|

|

4

|

Labeling speed

|

1200-2400 bottles/hour

|

|

5

|

Material

|

304 stainless steel

|

|

6

|

Program controller

|

Touch panel screen & PLC control

|

|

7

|

Air pressure

|

0.5 -0.7mpa

|

|

8

|

Power

|

1kw

|

|

9

|

Frequency inverter

|

Coreken

|

|

10

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

11

|

PLC

|

MAGS/INOVANCE

|

|

12

|

Touch screen

|

MAGS/INOVANCE

|

|

13

|

Sensor

|

SICK/KEYENCE

|

|

14

|

Pneumatic components

|

AirTAC

|

|

15

|

Machine size

|

1200x490x1100 (mm)

|

|

16

|

Weight

|

80 (KG)

|

|

17

|

Power supply

|

220V/50Hz

|

1 or 2 Sides Semi Auto Square Bottle Jar Labeling Machine

|

1

|

Machine name

|

1 or 2 Sides Square Bottle Jar Labeling Machine

|

|

2

|

Applicable square bottle size

|

L: 20-200mm

W: 20-150mm

|

|

3

|

Applicable labels size

|

Height: 15-110mm

Width: 15-100mm

|

|

4

|

Labeling speed

|

900-1800 bottles/hour

|

|

5

|

Material

|

304 stainless steel

|

|

6

|

Controller

|

Button control

|

|

7

|

Air pressure

|

0.5 -0.7mpa

|

|

8

|

Power

|

1kw

|

|

9

|

Touch screen

|

Samkoon / MAGS

|

|

10

|

PLC

|

Samkoon / MAGS

|

|

11

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

12

|

Pneumatic components

|

AirTAC

|

|

13

|

Machine size

|

850x400x720 (mm)

|

|

14

|

Weight

|

40 (KG)

|

|

15

|

Power supply

|

220V/50Hz

|

Share