Henwi HWFCL- 1 Nozzle Semi Auto Powder Filling Packing Machine Coffee Cocoa Ginger Bean Powder Screw Bottling Filling Packing Machine with Plastic & Aluminum Bottle Capping Labeling Machine Line

Henwi HWFCL- 1 Nozzle Semi Auto Powder Filling Packing Machine Coffee Cocoa Ginger Bean Powder Screw Bottling Filling Packing Machine with Plastic & Aluminum Bottle Capping Labeling Machine Line

Couldn't load pickup availability

1. Introduction

This equipment is widely used in powder material filling and bottling, especially in food, medicine, cosmetics, daily chemical industry, etc. It can work with capping machine and labeling machine and other machines as a production line.

This equipment uses a screw feeding system to accurately control the delivery of powder materials. After manual operation, the bottle is manually placed on the weighing machine to detect the weight.

Suitable for many different shape container, like bottle, jar, can, tin, sachet, barrel, tank, etc. Or different material container, like plastic, glass, aluminum, wood, paper, PET, iron steel, etc.

2. Specification

1 Nozzle Semi Auto Powder Filling Packing Machine with Powder Screw Feeder

|

1

|

Filling method

|

Screw metering (or electronic weighing)

|

|

2

|

Auger volume

|

30/50L(can be customized)

|

|

3

|

Feeder volume

|

100L(can be customized)

|

|

4

|

Machine material

|

SUS 304 (can be customized SUS316L)

|

|

5

|

Filling volume

|

1-1000g (can be customized)

|

|

6

|

Filling accuracy

|

±1%(different volume and material,accuracy will be little different)

|

|

7

|

Filling speed

|

20-30 BPM

|

|

8

|

Weight

|

200KG

|

|

9

|

Dimension

|

1100*750*1750mm

|

|

10

|

Protective device

|

Outage alarm on shortage of powder in the hopper.

|

Semi-Auto 4 Wheels Bottle Screwing Capping Sealing Machine

|

1

|

Qty of capping wheels

|

4 wheels

|

|

2

|

Applicable cap diameter

|

20-80mm

|

|

3

|

Capping speed

|

1200-1800 bottles/hour

|

|

4

|

Material

|

304 stainless steel

|

|

5

|

Controller

|

Button control

|

|

6

|

Automation

|

Desktop, semi automatic

|

|

7

|

Air pressure

|

0.5 -0.7mpa

|

|

8

|

Power

|

0.3kw

|

|

9

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

10

|

Motors

|

DY

|

|

11

|

Pneumatic components

|

AirTAC

|

|

12

|

Machine size

|

500x380x700 (mm)

|

|

13

|

Weight

|

35 (KG)

|

|

14

|

Power supply

|

220V/50Hz

|

|

1

|

Applicable cap diameter

|

50-200mm

|

|

2

|

Capping speed

|

1200-1800 bottles/hour

|

|

3

|

Material

|

304 stainless steel

|

|

4

|

Controller

|

Button control & trigger

|

|

5

|

Power

|

0.55kw

|

|

6

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

7

|

Inverter

|

SANLY

|

|

8

|

Motors

|

DY

|

|

9

|

Machine size

|

600x660x1450 (mm)

|

|

10

|

Weight

|

150 (KG)

|

|

11

|

Power supply

|

220V/50Hz

|

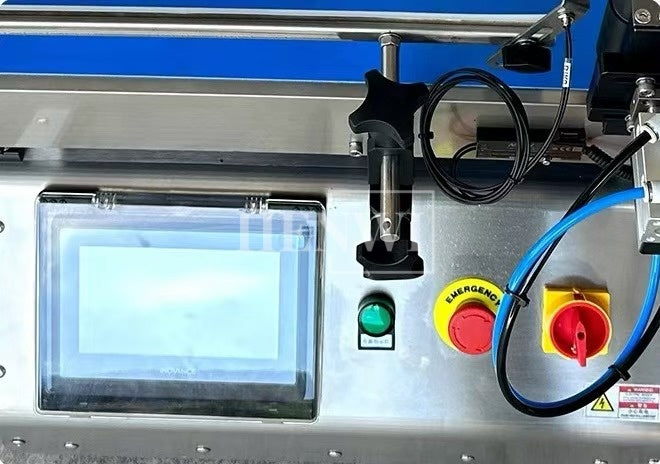

Vertical Semi Auto Model Round Bottle Labeling Machine

|

1

|

Machine name

|

Manual vertical model round bottle labeling machine

|

|

2

|

Applicable round bottle size

|

Diameter: 30-100mm

Height: 15-250mm

|

|

3

|

Applicable labels size

|

Hight: 15-130mm

|

|

4

|

Labeling speed

|

1200-2400 bottles/hour

|

|

5

|

Material

|

304 stainless steel

|

|

6

|

Program controller

|

Touch panel screen & PLC control

|

|

7

|

Air pressure

|

0.5 -0.7mpa

|

|

8

|

Power

|

1kw

|

|

9

|

Frequency inverter

|

Coreken

|

|

10

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

11

|

PLC

|

MAGS/INOVANCE

|

|

12

|

Touch screen

|

MAGS/INOVANCE

|

|

13

|

Sensor

|

SICK/KEYENCE

|

|

14

|

Pneumatic components

|

AirTAC

|

|

15

|

Machine size

|

1200x490x1100 (mm)

|

|

16

|

Weight

|

80 (KG)

|

|

17

|

Power supply

|

220V/50Hz

|

Share