Henwi HWFCL-2 Nozzles Automatic Granular Paste Sauce Jam Bottling Filling Machine with Automatic Iron Tinplate Cap Capping Feeding Sealing Machine with 2 Sides Square Bottle & Round Bottle Labeling Machine Line

Henwi HWFCL-2 Nozzles Automatic Granular Paste Sauce Jam Bottling Filling Machine with Automatic Iron Tinplate Cap Capping Feeding Sealing Machine with 2 Sides Square Bottle & Round Bottle Labeling Machine Line

Couldn't load pickup availability

1. Introduction

Please inquire us if you're not sure whether this machine can process your product or not.

This machine series is suitable for filling bottling packing granular food paste products or easy-solid-liquid-stratification products into bottle or jar or other containers, like chili paste, fruit jam, vegetable puree, seasoning sauce, gel, jelly, gelatin, etc. The material hopper is with mixing paddle to avoid sediment.

The machine uses stainless steel piston cylinder filling to ensure that the granular material or particle shape inside the paste is complete. At the same time, the hopper is equipped with a mixing paddle to ensure that the material is uniform and not stratified.

2. Specification

2 Nozzles Automatic Granular Paste Sauce Jam Bottling Filling Machine

|

1

|

Qty of filling head

|

2 heads

|

|

2

|

Filling range

|

50-200ML;

Customized

|

|

3

|

Filling speed

|

About 20~30 bottles/min

|

|

4

|

Filling accuracy

|

±1%.

|

|

5

|

Material

|

304 /316 stainless steel

|

|

6

|

Program controller

|

Touch panel screen & PLC control

|

|

7

|

Air pressure

|

0.6 -0.8mpa

|

|

8

|

Power

|

1.2kw

|

|

9

|

Capacity of material tank

|

100L

|

|

10

|

Protective device

|

Outage alarm on shortage of liquid in the reservoirtank.

|

|

11

|

Pump type

|

Piston pump

|

|

12

|

Frequency inverter

|

Schneider

|

|

13

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

14

|

PLC

|

Siemens / Weinview

|

|

15

|

Touch screen

|

Siemens / Weinview

|

|

16

|

Sensor

|

Omron

|

|

17

|

Motors

|

ZD

|

|

18

|

Pneumatic components

|

AirTAC

|

|

19

|

Machine size

|

2000*1600*1800 (mm)

|

|

20

|

Weight

|

600 (KG)

|

|

21

|

Power supply

|

220V/50Hz

|

Automatic Iron Tinplate Cap Capping Feeding Sealing Machine

|

1

|

Qty of capping wheels

|

1 wheel

|

|

2

|

Applicable bottle height

|

80-150mm (or customized)

|

|

3

|

Applicable bottle diameter

|

45-90mm (or customized)

|

|

4

|

Applicable cap diameter

|

38-85mm (or customized)

|

|

5

|

Capping speed

|

1800-2500 bottles/hour

|

|

6

|

Material

|

304 stainless steel

|

|

7

|

Conveyor speed

|

5-15 meter/min adjustable

|

|

8

|

Program controller

|

Touch panel screen & PLC control

|

|

9

|

Air pressure

|

0.5 -0.7mpa

|

|

10

|

Air comsuption

|

0.2m³/min

|

|

11

|

Power

|

1.5kw

|

|

12

|

Electrical components

|

Delixi/CHNT

|

|

13

|

PLC

|

Siemens / Weinview

|

|

14

|

Touch screen

|

Siemens / Weinview

|

|

15

|

Inverter

|

Schneider

|

|

16

|

Intermediate relay

|

Schneider

|

|

17

|

Proximity switch

|

Omron

|

|

18

|

DC24V

|

Meanwell

|

|

19

|

Motors

|

Maihua

|

|

20

|

Pneumatic components

|

AirTAC

|

|

21

|

Servo system

|

Ruineng

|

|

22

|

Machine size

|

2500x1300x2000 (mm)

|

|

23

|

Weight

|

500 (KG)

|

|

24

|

Power supply

|

220V/50Hz

|

|

1

|

Machine name

|

Automatic double sides square &

round bottle labeling machine

|

|

2

|

Applicable round bottle size

|

Diameter: 30-100mm

|

|

3

|

Applicable square bottle size

|

Width: 30-110mm

Length: 50-200mm

or customized

|

|

4

|

Applicable labels size

|

Hight: 15-130mm

|

|

5

|

Labeling speed

|

1500-6000 bottles/hour

|

|

6

|

Material

|

304 stainless steel

|

|

7

|

Program controller

|

Touch panel screen & PLC control

|

|

8

|

Air pressure

|

0.5 -0.7mpa

|

|

9

|

Power

|

3kw

|

|

10

|

Frequency inverter

|

Delta/Coreken

|

|

11

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

12

|

PLC

|

Siemens

|

|

13

|

Touch screen

|

Siemens

|

|

14

|

Servo parts

|

Inovance

|

|

15

|

Sensor

|

SICK/KEYENCE

|

|

16

|

Servo motors

|

ZD/TECO

|

|

17

|

Stepper motors

|

ZD

|

|

18

|

Pneumatic components

|

AirTAC

|

|

19

|

Machine size

|

2500x1500x1800 (mm)

|

|

20

|

Net weight

|

480 (KG)

|

|

21

|

Power supply

|

220V/50Hz

|

|

22

|

Wooden box packing size

|

2400x1400x2000 (mm)

|

3. Production Line

(1) Bottle Unscrambler

(2) SUS Storage Tank

(3) Automatic Bottling Filling Machine

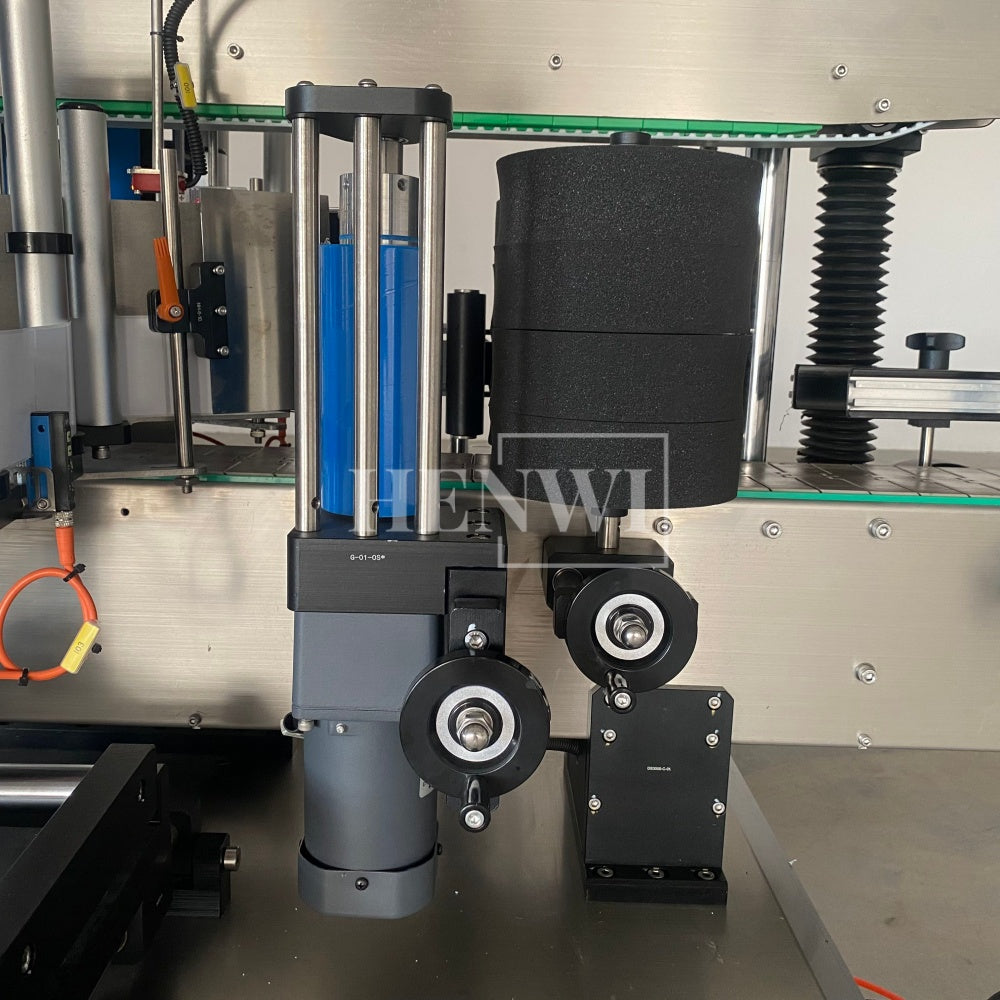

(4) Automatic Bottle Capping Machine

(5) Automatic Cap Feeding Machine

(6) Automatic Bottle Clamping Conveyor

(7) Aluminum Foil Induction Sealing Machine

(8) Automatic Bottle Labeling Machine

(9) Finished Bottle Collecting Table

(10) Other Accessory Machine

Share