Henwi HWFCL- 2 Nozzles Automatic Powder Filling Weighing Packing Machine Powder Bottling Canning Seaming Machine with Aluminum Cover Crimping Capping Sealing Machine Lid Crimper Capper Sealer with Soft Anti-Dust Cover Feeding Pressing Sealing Machine

Henwi HWFCL- 2 Nozzles Automatic Powder Filling Weighing Packing Machine Powder Bottling Canning Seaming Machine with Aluminum Cover Crimping Capping Sealing Machine Lid Crimper Capper Sealer with Soft Anti-Dust Cover Feeding Pressing Sealing Machine

Couldn't load pickup availability

1. Introduction

This equipment is widely used in powder material filling and bottling, especially in food, medicine, cosmetics, daily chemical industry, etc. It can work with capping machine and labeling machine and other machines as a production line.

Its main function is to accurately fill powdered materials into packaging containers through a screw feeding system according to the predetermined weight. Powder is weighed while filling. Suitable for filling and packaging medium-volume powder products

The first filling hopper weighs and fills the approximate weight of powder. The second hopper accurately compensates for the remaining weight of powder.

Suitable for many different shape container, like bottle, jar, can, tin, sachet, barrel, tank, etc. Or different material container, like plastic, glass, aluminum, wood, paper, PET, iron steel, etc.

2. Specification

2 Nozzles Automatic Powder Filling Weighing Packing Machine

|

1

|

Filling method

|

Screw metering / Cup metering

|

|

2

|

Auger volume

|

30/50L(can be customized)

|

|

3

|

Feeder volume

|

100L(can be customized)

|

|

4

|

Machine material

|

SUS 304 (can be customized SUS316L)

|

|

5

|

Filling volume

|

200-2000g,

500-5000g,

|

|

6

|

Filling accuracy

|

±1%(different volume and material,accuracy will be little different)

|

|

7

|

Filling speed

|

40-60 BPM

|

|

8

|

Touch screen+PLC

|

Siemens

|

|

9

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

10

|

Photoelectric sensor

|

SICK/AUTONIX

|

|

11

|

Inverter

|

Delta

|

|

12

|

Servo motor

|

INOVANCE / ZD

|

|

13

|

Weight

|

900KG

|

|

14

|

Dimension

|

4500*1200*2200mm

|

|

15

|

Protective device

|

Outage alarm on shortage of powder in the hopper.

|

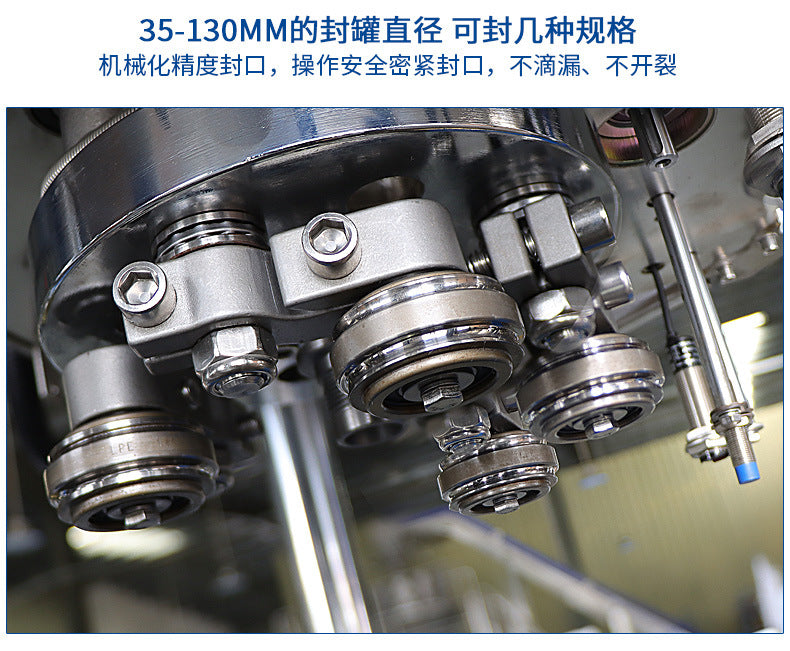

Automatic Aluminum Cover Crimping Capping Sealing Machine

|

1

|

Number of sealing head

|

1

|

|

2

|

Number of sealing rollers

|

4 (2 first operation sealing rollers, 2 second operation sealing rollers)

|

|

3

|

Can sealing speed

|

20-50 cans/minute (adjustable, related to the material, size and content of the can)

|

|

4

|

Can sealing height

|

25-220mm (large height span requires additional molds)

|

|

5

|

Can sealing diameter

|

30-110MM (8 stations), 60-160MM (6 stations)

|

|

6

|

Air consumption

|

150L/min

|

|

7

|

Working air pressure

|

≥0.6MPa

|

|

8

|

Total power

|

1.7KW

|

|

9

|

Net weight

|

330KG (approx.)

|

|

10

|

Gross weight

|

400KG (approx.)

|

|

11

|

Conveyor belt height

|

850mm

|

|

12

|

Main material of equipment

|

SUS304

|

|

13

|

Machine size

|

L 2400*W 850*H 165mm (approx.)

|

|

14

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

15

|

Inverter

|

Delta

|

|

16

|

Servo motor

|

INOVANCE

|

|

17

|

Touch screen+PLC

|

Siemens

|

|

18

|

Photoelectric sensor

|

SICK/AUTONIX

|

|

19

|

Power supply

|

220V/50/60Hz

|

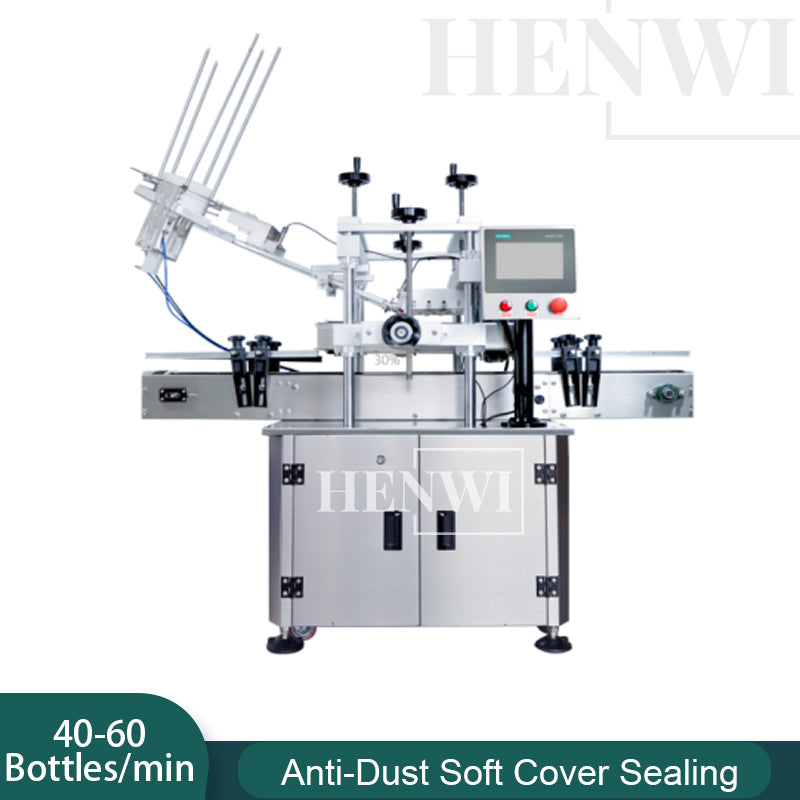

Soft Anti-Dust Cover Feeding Pressing Sealing Machine

|

1

|

Capping Speed

|

40-60 cans/minute

|

|

2

|

Can Diameter

|

40-130mm

|

|

3

|

Can Height

|

50-220mm

|

|

4

|

Conveyor Belt Speed

|

0-10 meters/minute (Adjustable)

|

|

5

|

Power Supply

|

220V 50/60Hz

|

|

6

|

Power

|

1.2kW

|

|

7

|

Working air pressure

|

0.4-0.6MPa

|

|

8

|

Total power

|

1.7KW

|

|

9

|

Touch screen+PLC

|

Siemens

|

|

10

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

11

|

Photoelectric sensor

|

SICK/AUTONIX

|

|

12

|

Inverter

|

Delta

|

|

13

|

Servo motor

|

INOVANCE / ZD

|

|

14

|

Main material of equipment

|

SUS304

|

|

15

|

Machine weight

|

400KG (approx.)

|

|

16

|

Machine size

|

L 3000*W 920*H 1860mm (approx.)

|

Share