Henwi HWFCL- 2 Nozzles Semi-Auto Liquid Bottling Filling Packing Machine 2 Head Bottle Horizontal Filler with Semi Auto Desktop Model Cap Capping Sealing Machine with Semi Auto Round Bottle Labeling Machine Line

Henwi HWFCL- 2 Nozzles Semi-Auto Liquid Bottling Filling Packing Machine 2 Head Bottle Horizontal Filler with Semi Auto Desktop Model Cap Capping Sealing Machine with Semi Auto Round Bottle Labeling Machine Line

Couldn't load pickup availability

1. Introduction

Please inquire us if you're not sure whether this machine can process your product or not.

This machine series is suitable for filling bottling packing liquid cosmetics & food & pharmaceutical & chemical products into bottle or jar or other containers, like body cream, skincare lotion, conditioner, concealer, nail polish, lubricant, engine oil, ointment, balm oil, jam, food paste, pie, mayonnaise, ketchup, salad sauce, sauce dressing, butter, wax, petroleum jelly, scented candle, shampoo, liquid soap, liquid laundry detergent, shower gel, dishwasher paste, dish soap, mouthwash water, car wash water, glass cleaner, hair serum, vape liquid, hand sanitizer, water base paint, liquid fertilizer, liquid pesticide, liquid insecticide, etc.

It is named with its working principle like a piston, sucking liquid material from storage tank, then filling into bottle or other vessel. Anti-foaming, high precision, no dripping, diversified filling volume, easy operation. It can work with capping machine and labeling machine and other machines as a production line.

2. Specification

2 Nozzles Semi-Auto Liquid Bottling Filling Packing Machine

|

1

|

Qty of filling head

|

2 heads

|

|

2

|

Filling range

|

50-500ML;

100-1000ML;

300-3000ML;

500-5000ML

|

|

3

|

Filling speed

|

1200-3600 bottles/hour

|

|

4

|

Filling accuracy

|

±1%.

|

|

5

|

Material

|

304 stainless steel

|

|

6

|

Air pressure

|

0.4 -0.6mpa

|

|

7

|

Capacity of material tank

|

30L

|

|

8

|

Pump type

|

Piston pump

|

|

9

|

Material feeding method

|

Direct suction/Manual

|

|

10

|

Pneumatic components

|

AirTAC

|

|

11

|

Machine size

|

1400*600*600 (mm)

|

|

12

|

Weight

|

45 (KG)

|

|

13

|

Piston direction |

Horizontal filling

|

Semi-Auto 4 Wheels Bottle Screwing Capping Sealing Machine

|

1

|

Qty of capping wheels

|

4 wheels

|

|

2

|

Applicable cap diameter

|

20-80mm

|

|

3

|

Capping speed

|

1200-1800 bottles/hour

|

|

4

|

Material

|

304 stainless steel

|

|

5

|

Controller

|

Button control

|

|

6

|

Automation

|

Desktop, semi automatic

|

|

7

|

Air pressure

|

0.5 -0.7mpa

|

|

8

|

Power

|

0.3kw

|

|

9

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

10

|

Motors

|

DY

|

|

11

|

Pneumatic components

|

AirTAC

|

|

12

|

Machine size

|

500x380x700 (mm)

|

|

13

|

Weight

|

35 (KG)

|

|

14

|

Power supply

|

220V/50Hz

|

Vertical Semi Auto Model Round Bottle Labeling Machine

|

1

|

Machine name

|

Manual vertical model round bottle labeling machine

|

|

2

|

Applicable round bottle size

|

Diameter: 30-100mm

Height: 15-250mm

|

|

3

|

Applicable labels size

|

Hight: 15-130mm

|

|

4

|

Labeling speed

|

1200-2400 bottles/hour

|

|

5

|

Material

|

304 stainless steel

|

|

6

|

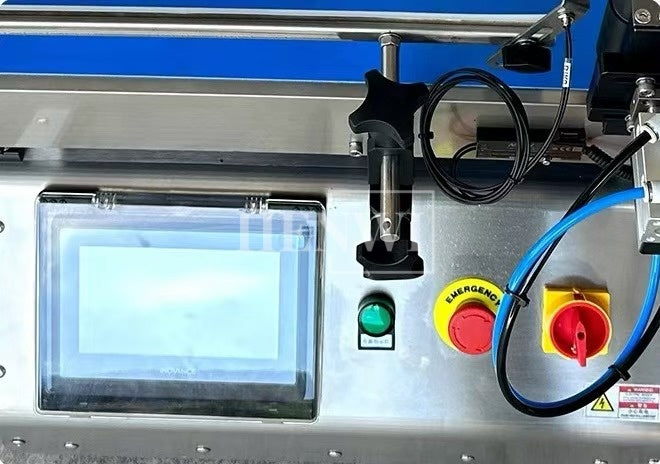

Program controller

|

Touch panel screen & PLC control

|

|

7

|

Air pressure

|

0.5 -0.7mpa

|

|

8

|

Power

|

1kw

|

|

9

|

Frequency inverter

|

Coreken

|

|

10

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

11

|

PLC

|

MAGS/INOVANCE

|

|

12

|

Touch screen

|

MAGS/INOVANCE

|

|

13

|

Sensor

|

SICK/KEYENCE

|

|

14

|

Pneumatic components

|

AirTAC

|

|

15

|

Machine size

|

1200x490x1100 (mm)

|

|

16

|

Weight

|

80 (KG)

|

|

17

|

Power supply

|

220V/50Hz

|

Share