Henwi HWFCL- Full Auto Acid / Alkaline Liquid Chemical Disinfectant Water-Based Pesticide PP Mixer Machine Tank Corrosion Resistance Mixing Machine Anti Corrosive Filling Capping Labeling Machine Production Line

Henwi HWFCL- Full Auto Acid / Alkaline Liquid Chemical Disinfectant Water-Based Pesticide PP Mixer Machine Tank Corrosion Resistance Mixing Machine Anti Corrosive Filling Capping Labeling Machine Production Line

Couldn't load pickup availability

1. Introduction

Please inquire us if you're not sure whether this machine can process your product or not.

The PP plastic mixer is mainly used in chemical, petroleum, and other industrial lines. It is specially for the strong causticity product. Such as the strong acid and alkaline liquid, bleach, disinfectant, kitchen cleaner, toilet cleaner, insecticide, pesticide, liquid fertilizer, etc.

2. Specification

PP Mixer Machine Tank Corrosion Resistance Mixing Machine

|

1

|

Tank capacity

|

500L

|

1000L

|

2000L

|

3000L

|

5000L

|

|

2

|

Mixing motor

|

2.2KW

|

4KW

|

5.5KW

|

7.5KW

|

11KW

|

|

3

|

Tank lid

|

Half-opened lid

|

||||

|

4

|

Power supply

|

380V/50Hz

|

||||

|

5

|

Tank material

|

PP / PVC / Customized

|

||||

|

6

|

Frame material

|

SUS304

|

||||

|

7

|

Mixing paddle material

|

Enamel

|

||||

|

8

|

Mixing motor

|

Explosion-Proof Motor

|

||||

|

9

|

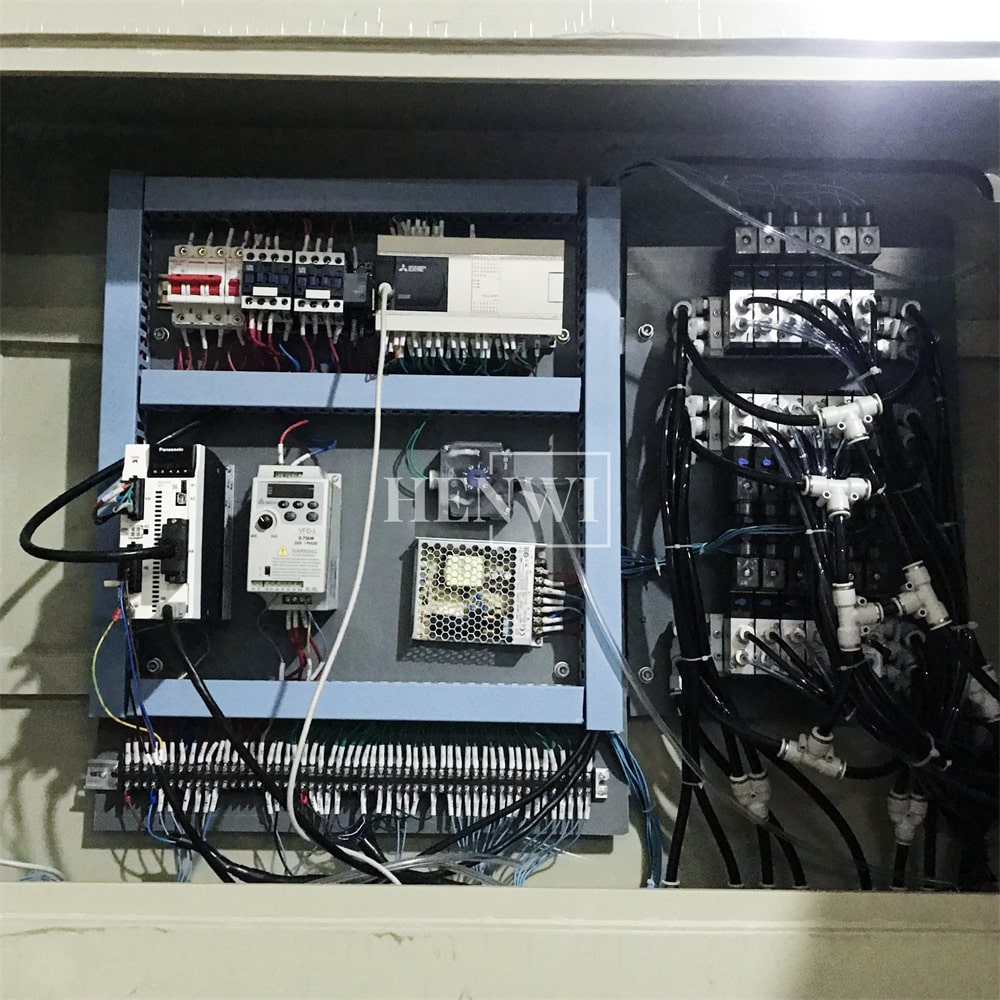

Control

|

Anti-Explosive Button Control Electricity Box

|

||||

|

10

|

Mixing speed

|

0-63rpm

|

||||

|

11

|

Work temperature

|

(PP)-10°C~100°C (PVC)-10℃ to 60℃

|

||||

PP Liquid Filter

|

1

|

Specification: Testing liquid: Water S.G. 1.0

|

||||||

|

2

|

Model

|

BFD-2001

|

BFD-2004

|

BFD-2006

|

BFD-3006

|

BFD-2018

|

BFD-3018

|

|

3

|

Filtration(m³)

|

3

|

5

|

10/15

|

15-20

|

20-25

|

30-50

|

|

4

|

Barrel diameter(mm)

|

140

|

200

|

280

|

280

|

450

|

450

|

|

5

|

Filter bag material

|

PP

NMO

SUS

|

PP

NMO

SUS

|

PP

NMO

SUS

|

PP

NMO

SUS

|

PP

NMO

SUS

|

PP

NMO

SUS

|

|

6

|

Filter bag size(mm)

|

105*450

|

150*450

|

180*450

|

180*810

|

180*450

|

180*810

|

|

7

|

Filter bag qty(pcs)

|

1

|

1

|

1

|

1

|

2/3

|

2/3

|

|

8

|

Suitable temperature(℃)

|

75

|

75

|

75

|

75

|

75

|

75

|

|

9

|

Connection

|

Union

|

Union

|

Flange

|

Flange

|

Flange

|

Flange

|

|

10

|

Caliber(mm)

|

25-32

|

25-32

|

50-63

|

50-63

|

63-90

|

63-110

|

PP Liquid Storage Tank

|

Tank Capacity(L)

|

Tank Diameter(mm)

|

Foot Distance(mm)

|

Tank Length(mm)

|

Tank Thickness(mm)

|

|

500

|

700

|

500

|

1500

|

14

|

|

1000

|

800

|

1100

|

2240

|

14

|

|

2000

|

1200

|

800

|

2100

|

14

|

|

3000

|

1200

|

1400

|

3000

|

14

|

|

4000

|

1400

|

1400

|

3100

|

14

|

|

5000

|

1400

|

1800

|

3700

|

15

|

|

6000

|

1600

|

1600

|

3400

|

15

|

|

8000

|

1800

|

1700

|

3700

|

15

|

|

10000

|

1800

|

2200

|

4500

|

16

|

|

12000

|

1800

|

2500

|

5250

|

16

|

|

15000

|

2000

|

2500

|

5300

|

16

|

|

20000

|

2200

|

3500

|

6050

|

18

|

|

25000

|

2400

|

3500

|

6200

|

18

|

|

30000

|

2600

|

3500

|

6450

|

20

|

Automatic 4-32 Nozzles Gravity Flow Model Anti Corrosive Liquid Chemical Filling Machine

|

1

|

Qty of filling head

|

12 heads (4-32 nozzles customized)

|

|

2

|

Filling capacity

|

50-5000ml (Customized)

|

|

3

|

Filling speed

|

50-70 bpm (ref. 500ml)

|

|

4

|

Filling accuracy

|

±1%.

|

|

5

|

Material

|

PP/SUS316L

|

|

6

|

Filling way

|

Self-flowing by gravity

|

|

7

|

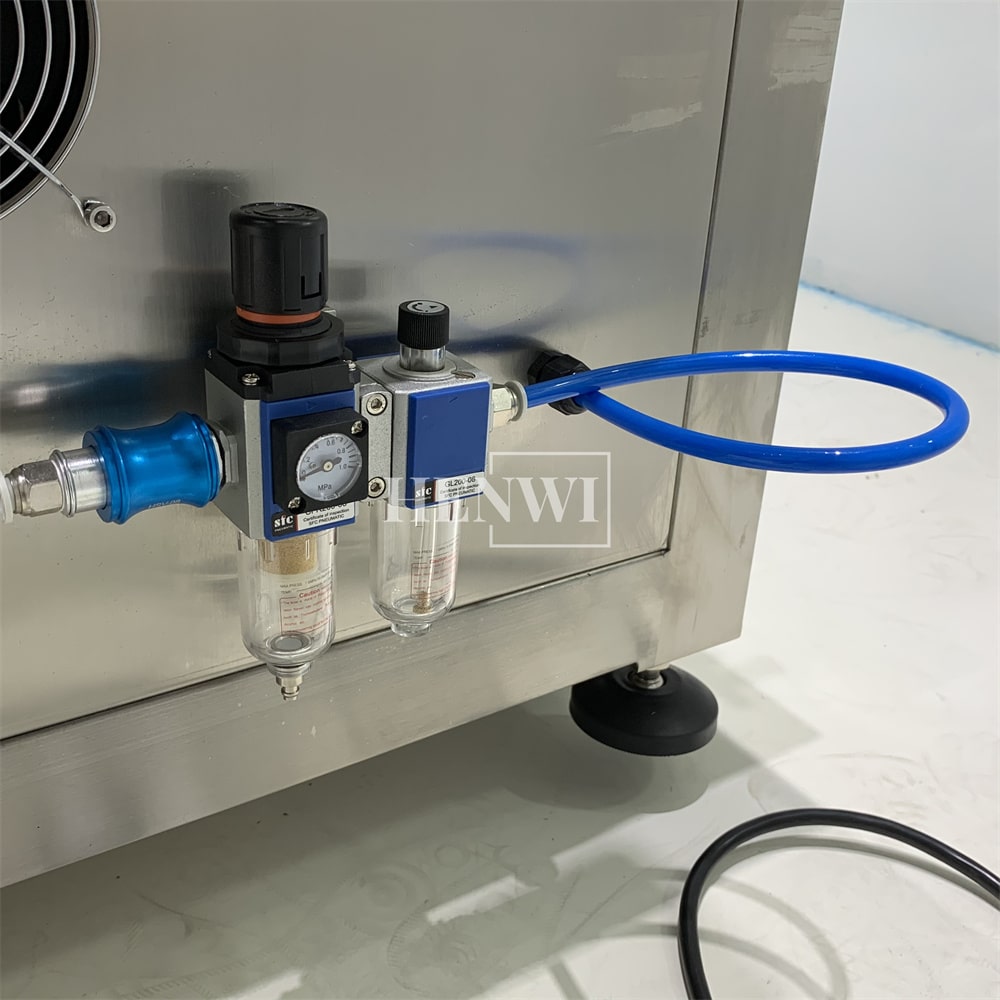

Air pressure

|

0.6 -0.8mpa

|

|

8

|

Voltage

|

220V/50Hz

|

|

9

|

Machine size

|

3500*1200*2000mm

|

| 10 |

Weight

|

650kg

|

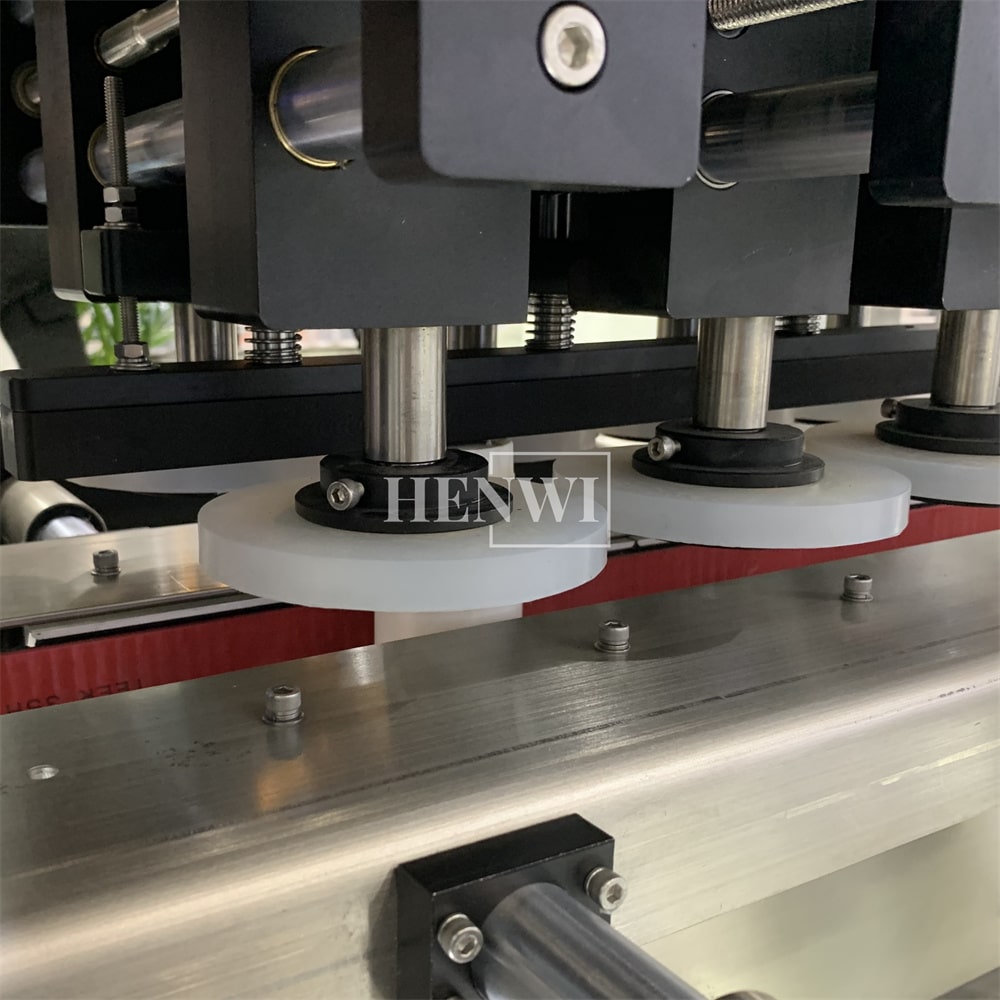

8 Wheels High Speed Continously Bottle Capping Sealing Machine with Cap Elevator Feeding Machine

|

1

|

Qty of capping wheels

|

8 wheels

|

|

2

|

Applicable cap diameter

|

30-100mm

|

|

3

|

Capping speed

|

3000-4200 bottles/hour

|

|

4

|

Material

|

304 stainless steel

|

|

5

|

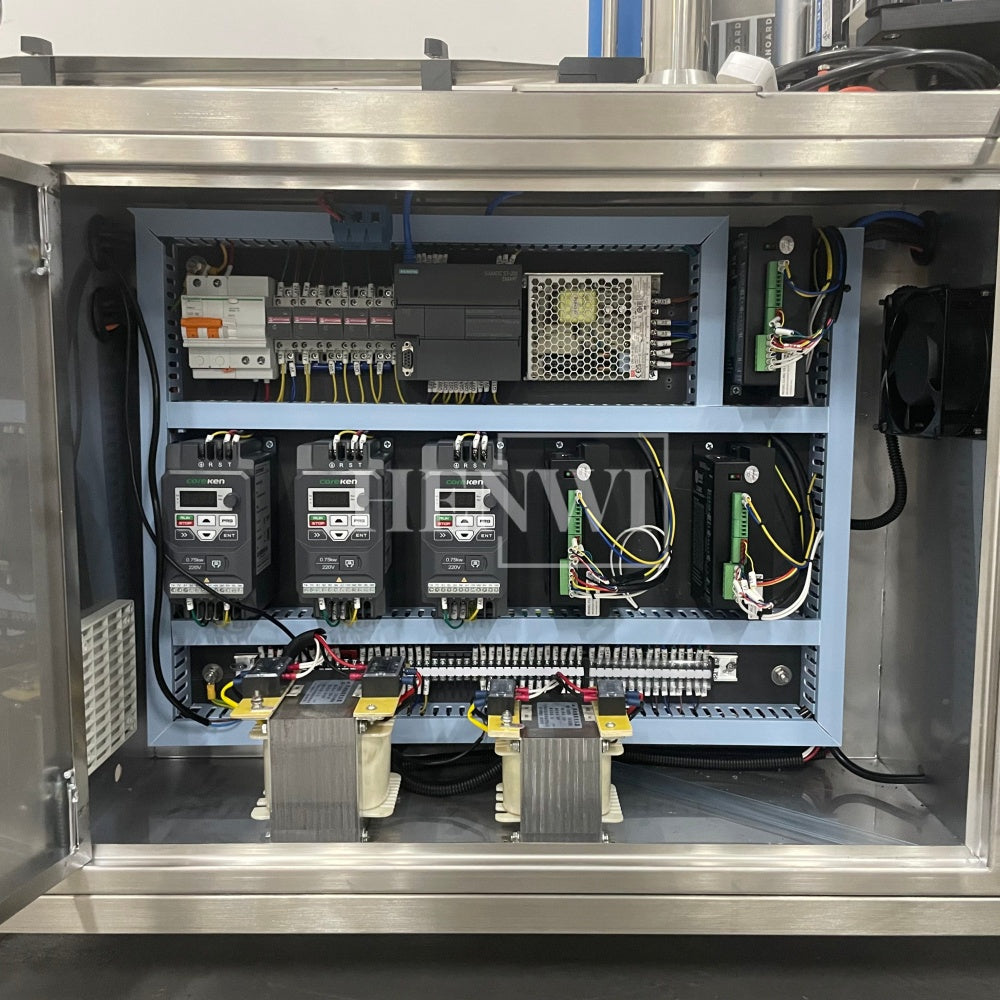

Program controller

|

Touch panel screen & PLC control

|

|

6

|

Air pressure

|

0.5 -0.7mpa

|

|

7

|

Power

|

3kw

|

|

8

|

Frequency inverter

|

Delta/Coreken

|

|

9

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

10

|

PLC

|

NO

|

|

11

|

Touch screen

|

NO

|

|

12

|

Sensor

|

SICK/KEYENCE

|

|

13

|

Motors

|

ZD

|

|

14

|

Pneumatic components

|

AirTAC

|

|

15

|

Machine size

|

3000x900x2000 (mm)

|

|

16

|

Weight

|

500 (KG)

|

|

17

|

Power supply

|

220V/50Hz

|

|

1

|

Machine name

|

Automatic double sides square &

round bottle labeling machine

|

|

2

|

Applicable round bottle size

|

Diameter: 30-100mm

|

|

3

|

Applicable square bottle size

|

Width: 30-110mm

Length: 50-200mm

or customized

|

|

4

|

Applicable labels size

|

Hight: 15-130mm

|

|

5

|

Labeling speed

|

1500-6000 bottles/hour

|

|

6

|

Material

|

304 stainless steel

|

|

7

|

Program controller

|

Touch panel screen & PLC control

|

|

8

|

Air pressure

|

0.5 -0.7mpa

|

|

9

|

Power

|

3kw

|

|

10

|

Frequency inverter

|

Delta/Coreken

|

|

11

|

Electrical components

|

Delixi/CHNT/Schneider

|

|

12

|

PLC

|

Siemens

|

|

13

|

Touch screen

|

Siemens

|

|

14

|

Servo parts

|

Inovance

|

|

15

|

Sensor

|

SICK/KEYENCE

|

|

16

|

Servo motors

|

ZD/TECO

|

|

17

|

Stepper motors

|

ZD

|

|

18

|

Pneumatic components

|

AirTAC

|

|

19

|

Machine size

|

2500x1500x1800 (mm)

|

|

20

|

Net weight

|

480 (KG)

|

|

21

|

Power supply

|

220V/50Hz

|

|

22

|

Wooden box packing size

|

2400x1400x2000 (mm)

|

3. Production Line

(1) Bottle Unscrambler

(2) SUS Storage Tank

(3) Automatic Bottling Filling Machine

(4) Automatic Bottle Capping Machine

(5) Automatic Cap Feeding Machine

(6) Automatic Bottle Clamping Conveyor

(7) Aluminum Foil Induction Sealing Machine

(8) Automatic Bottle Labeling Machine

(9) Finished Bottle Collecting Table

(10) Other Accessory Machine

Share