Henwi HWHM-F-500L Fixed Platform Model Half-Opened Foldable Cover Homogenizing Heating Mixer Tank Machine

Henwi HWHM-F-500L Fixed Platform Model Half-Opened Foldable Cover Homogenizing Heating Mixer Tank Machine

Couldn't load pickup availability

1. Introduction

Please inquire us if you're not sure whether this machine can process your product or not.

This machine series is suitable for making daily chemical & other low viscous liquid products, like shampoo, liquid soap, liquid laundry detergent, shower gel, dishwasher paste, dish soap, mouthwash water, car wash water, glass cleaner, hair serum, vape liquid, hand sanitizer, water base paint, liquid fertilizer, liquid pesticide, liquid insecticide, liquid air fresher, etc.

2. Specification

|

1

|

Model:

|

HWHM-F-500L

|

|

2

|

Working capacity

|

500Liters

|

|

3

|

Heating method

|

Steam/electric

|

|

4

|

Mixing type

|

Upper frame oar scraper mixer

|

|

5

|

Mixing motor power

|

3KW

|

|

6

|

Mixing frequency inverter

|

3KW

|

|

7

|

Mixing speed

|

0-65rpm

|

|

8

|

Homogenizer type

|

Bottom homogenizer

|

|

9

|

Homogenizer frequency inverter

|

5.5KW

|

|

10

|

Homogenizer speed

|

0-3000rpm(50Hz)/0-3600rpm(60Hz)

|

|

11

|

Control method

|

Button control

|

|

12

|

Frequency inverter

|

Delta

|

|

13

|

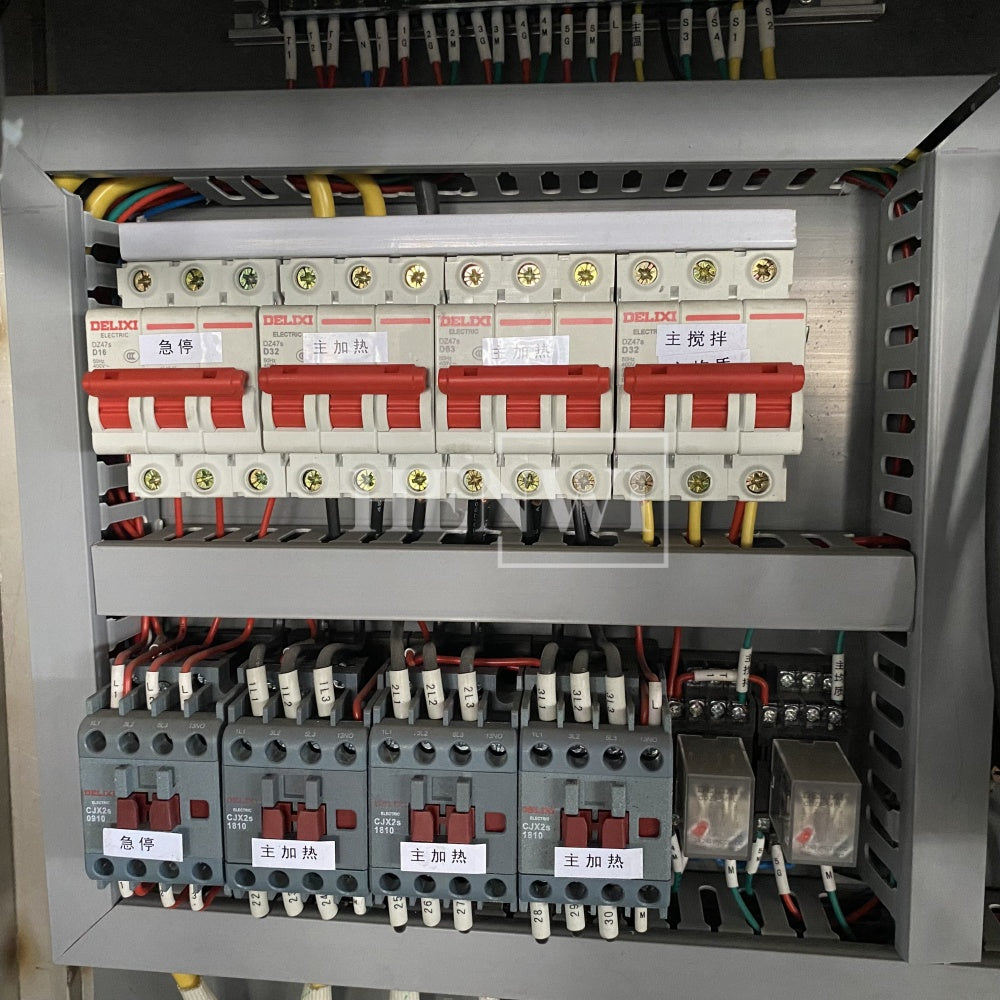

Electrical components

|

Delixi

|

|

14

|

Jacket

|

Double jacket,3 layers

|

|

15

|

Tank's materials

|

Inner layer 4mm/SUS316

Middle layer 3mm/SUS304 Outer layer 2mm/SUS304 |

|

16

|

Power supply

|

Standard: 380V/50Hz

220V/380V/415V/440V/3 phase(Optional)

|

3. Production Line

(1) Water Purification Treatment Device

(2) Raw Water Tank & Pure Water Tank

(3) Liquid Homogenizing Heating Mixer Machine

(4) SUS Storage Tank

(5) Automatic Bottling Filling Machine

(6) Automatic Bottle Capping Machine

(7) Automatic Bottle Labeling Machine

(8) Other Accessory Machine

4. Working Principle

(1) Adding materials and initial stirring:

Add various raw materials into the mixing pot and start initial mixing by rotating the stirring blades. At this time, the stirring system mainly plays the role of evenly distributing and mixing the materials.

(2) Homogenization:

While stirring, the homogenizer starts to work. The high-speed rotating homogenizing blades give the material high shear treatment, breaking large particles into fine particles to form a fine and uniform emulsion or suspension.

(3) Heating/cooling treatment:

Depending on the process requirements, the material can be heated or cooled by the jacket to control the material temperature. Heating helps some raw materials dissolve or react, while cooling can quickly reduce the material temperature after processing.

(4) Discharging:

When the material reaches the required uniformity and quality, the final product is discharged through the discharge port at the bottom of the pot for subsequent packaging.

5. Main Parts of Machine

Share